Metal-organic frameworks (MOFs), an emerging class of porous crystalline materials, have shown great promise in fields ranging from gas storage and separation to catalysis and biomedicine. However, MOF powders are notoriously difficult to dissolve and melt, and MOF thin films are often hard and brittle, making it extremely challenging to process these materials into functional forms. This has long been a bottleneck in integrating these materials into practical applications.

Now, a research team led by Professor ZHAO Junjie from the College of Chemical and Biological Engineering at Zhejiang University has found a solution: a novel wrinkled configuration for MOF thin films. Their approach, detailed in a study published in Science on August 9, 2024, introduces stretchability to MOF films and opens up new possibilities for their use in separation membranes and flexible electronics.

Prof. ZHAO Junjie (right) and his students

Innovative “wrinkled” configuration

MOF materials are renowned for their ultra-high specific surface area, versatile chemical properties, and easily tunable pore structures, making them valuable for various applications. However, MOF thin films are typically hard and brittle, limiting their manipulation and integration into functional form factors for areas such as membrane separation, electronic devices, and medical equipment.

Professor ZHAO and coworkers have developed a highly ingenious solution to enhance the flexibility of MOF films by introducing “wrinkled” configurations. This design not only increases the active surface area but also improves deformation capabilities, transforming the films from brittle and prone to breaking into flexible and resilient structures.

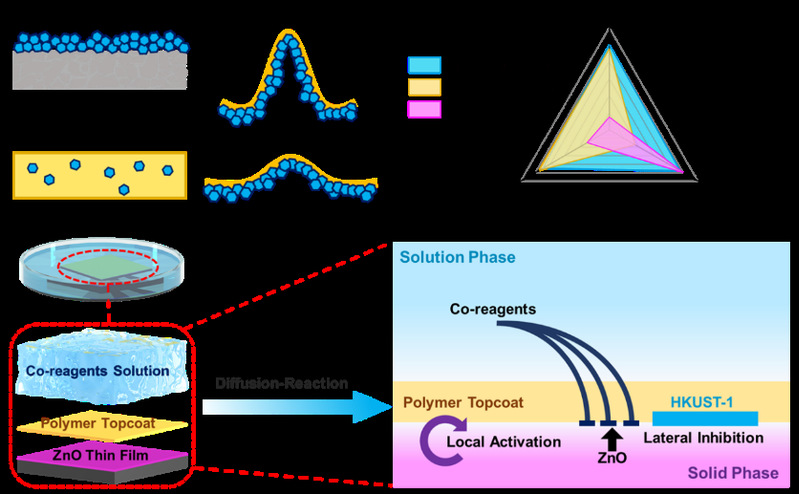

Fig. 1. Wrinkled configuration of MOF thin films with Turing patterns to enable plug-and-play integration.

The method reported in this work was inspired by Alan Turing, who first described in 1952 to explain pattern formation in nature. These patterns arise from the interplay between chemical substances in a process where reaction is coupled with diffusion. By applying this concept, the research team developed a confined interface synthesis method. They added a polymer topcoat to provide a confined venue for the interfacial reaction on an atomic layer deposited (ALD) ZnO surface. Within this confined space, the reagents for synthesizing MOFs diffuse from top to bottom, while the alkaline hydrolysis product released from the zinc oxide surface diffuse from bottom to top, forming a set of chemical waves traveling in counter directions. Through mathematical modeling and numerical simulation, the researchers found that by adjusting the “reaction-diffusion” conditions, they could obtain various instability states, thereby generating Turing patterns.

Furthermore, by altering the concentration of the reaction reagents and the thickness of the polymer topcoat in experiments, the research team created five categories of Turing patterns in MOF thin films, totaling 13 different motifs. These wrinkled MOF films feature adjustable morphologies, encompassing classic labyrinthine stripes, dots, rings, and other patterns similar to natural patterns found in animals like moray eels, box puffer and leopards.

Unleashing the potential of MOF thin films

Not only do wrinkled configurations significantly increase the effective surface area of MOF films, but they also endow the films with exceptionable flexibility, allowing them to withstand a maximum strain of 53.2%, a marked improvement over the sub-0.3% strain limit of traditional MOF materials.

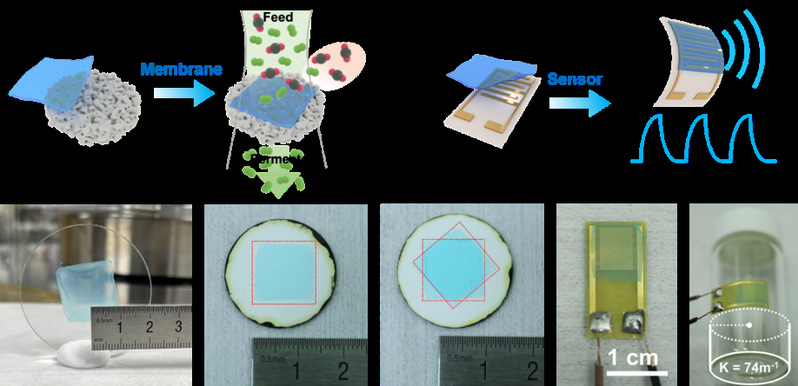

The superior mechanical properties of wrinkled MOF films enable them to be easily transferred to various substrates, much like a “sticker.” The researchers transferred them onto substrates such as plexiglass, porous ceramics, and pre-patterned electrodes on soft substrates, and found that MOF films’ structure and performance remained intact.

Fig. 2. Wrinkled MOF films can be flexibly transferred onto various substrates for 'plug-and-play' application.

Using this flexible transfer method, the research team developed gas separation membranes based on MOF materials, achieving efficient separation of hydrogen from carbon dioxide. Additionally, they transferred wrinkled MOF films onto flexible electrodes, creating soft humidity sensors. These applications highlight the “plug-and-play” potential of MOF films.

“This research paves the way for new configurations of MOF films, decoupling the film synthesis process from functional integration and expanding the range of possible applications,” says Professor ZHAO. “We hope our work will advance the development of sustainable chemical industries, wearable devices, and biomedicalgadgets.”

(From ZJU NEWSROOM)